CONTACT

Tel:+86-319-7109933

Tel: +86-319-7109988

Fax:+86-319-7109922

Email:lilixin@plpump.com

Email:sales@plpump.com

Address: No. 69, Lincheng Road, Lincheng Economic Development Zone, Lincheng County, Xingtai City, Hebei Province

WQ Non-clogging sewage submersibe pump

Outline

Model WQ non-clogging submersibie sewage pump is a new generation product successfullyrese- arched and designed, integrates foreign advanced technology with the trait of domestic pump. Featur-ing a remarkable effect of energy saving, guard against the winding, non clogging and automatic control. Have a distinctive effect to discharge solid particle and long fibre rubbish.

This series pumnp adopts special impelier structure and new mechanical seal, can transport the solid med-ium and long fibre effectively. Compared with tradi-tional impeller, this impeller adopts the single channel or double channel, which is similar to identical cross section elbow that has the same size, and have very good ability of circulation. It can run without vibra-tion through balance test of the impeller when collo-cate with the rational volute room.

The pump has a lead mature waterpower perfor-mance, through test, all performance indexes comply with relative requirements. A fter put for market, it receives great welcome and good comment support for special efficiency, reliable performance, and ste-ady quality.

Conditions of Use

1.The medium temperature should not be over 60C, density is 1.0~ 1.3 kg/dm', PH value is within5~ 9.

2.Pump has no an inner self-flowing circulation cooling system, the motor part outsides liquid should not exceed its 1/2.

3. Generally, ensure the motor do not overload within the range of using head. If it is necessary to work under all

head, please make a separate note in advance so as to manufacture.

4. When running, the current should not exceed the motor's rated current.

Features of Product

1. Adopt large -channel anti-jamming impeller structure, improve filth through ability , can be effective to pass 5 times of fibre through the caliber, diameler of pump require about 30% diameter of solid medium .

2. Reasonable design, reasonable necessary motor, high efficiency, effective energy-saving.

3. Mechanical seal adopts the new-type hard quality and is able to bear the rotten carbonization tungsten material, featuring a durable and wearable, can make pump run more than 8000 hours in succession safely.

4. Whole structure compactness, small, the lttlte volume, move conveniently install easily, It does not need to build the pump house, slipping into water can work, reduce the fabrication cost.

5. Set up high-accuracy anti-interference to leak and measure the sensor in the sealed oil room, and the temperature sensing component has been buried in the stator winding, can protect the pump definitely.

6. Can collocate the switch board of full-automatic safe protection based on the needs of user, protect the pump when leak water, leak electricity, overload and ultra warm definitely, improve security and dependability of the products.

7. Can collocate the automatic coupling of double guide rails, it is convenient to install and maintain, people needn't enter the sewage hole for this.

8. The floater switch can be changed according to the necessary liquid, the starting and stopping of the automatically controlled pump, not needing special messenger to guard, it is extremely convenient to use.

9. Guarantee the motor do not overload within the range of the whole head.

10. According t0 using occasion, the motor may adopt dyadic water jacket outside cycle cooling system, ensure the pump work w ithout water (dry style) safely.

11. There are two kinds of different installation ways, fixed style auto coupling installing system, removing style free installing systerm.

The meaning of the type

Applicable fields

1. Factories and commercial zone have serious poluted water enissions.

2. Urban sewage treatment plant's drainage system.

3. Residential district sewage row of water station.

4. Civil air defense system row of water station.

5. Polluted water drainage of hospital and hotel,

6. Public work, construction site.

7. Assembly machines on exploration and mine

8. Countryside methane-generating pit, irrigation

9. The water supply equipment in water station.

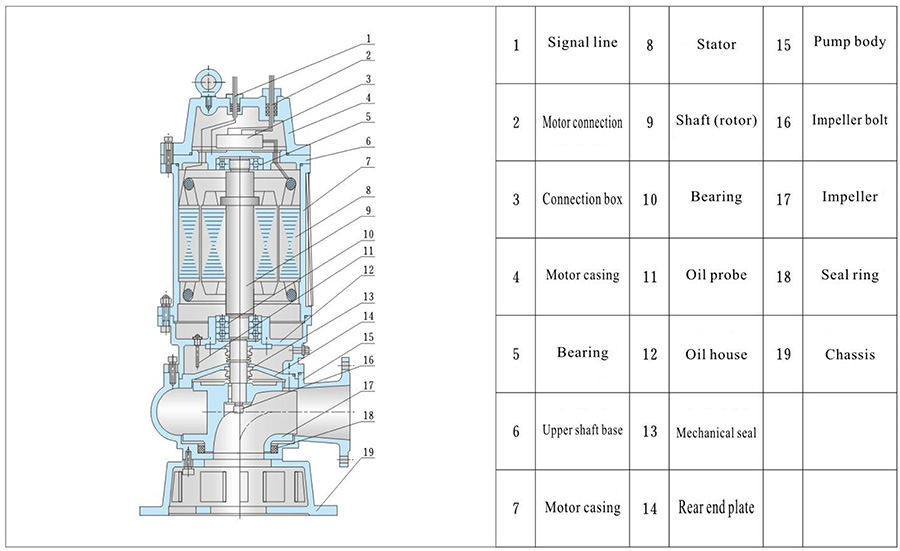

Structure Explanation

WQ model non-clogging submersible sewage pump consi-sts of electric motor and pump. The two parts separates through the oil separate room and machinery seal subassembly, belong to the integration of machinery with electronics product. Both motor and pump are co-axial (rotor), the length of whole pump is short, compact structure. Loaded with various protecting equipments, make the pump running safety and reliably.

Major parts as follows:

Signal line 1: Equip with the full-automatic safeguard control cabinet, all-direction to protect the pump, include water leak, loss of phase, short circuit, superheating, and overload of the motor.

Electric motor stator 8: Adopt B class or F class to be insulated.

Water-leakage probe 11: That part is installed in the oil roomn, when the mechanical seal damaged, water enters the oil room, the probe will give a warning signal, make the control system to protect the pump.

Mechanical seal 13: Two ways of the seal are in series with each other, and the material is anti-corrosive tungsten carbide, featuring a reliable seal, wear-resisting and long durable.

Impeller 17; Adopt the single channel or double channel, transport liquid effectively, can transport large matters and fibre rubbish, cut down the breakdown of clogging and winding.

Pump body 15: Match the impeller for use.

Seal-ring18: Installs in the pump body ring place, when the ring is worn for the running of impeller, seal ring can be changed, so as to guard pump running efficiency.

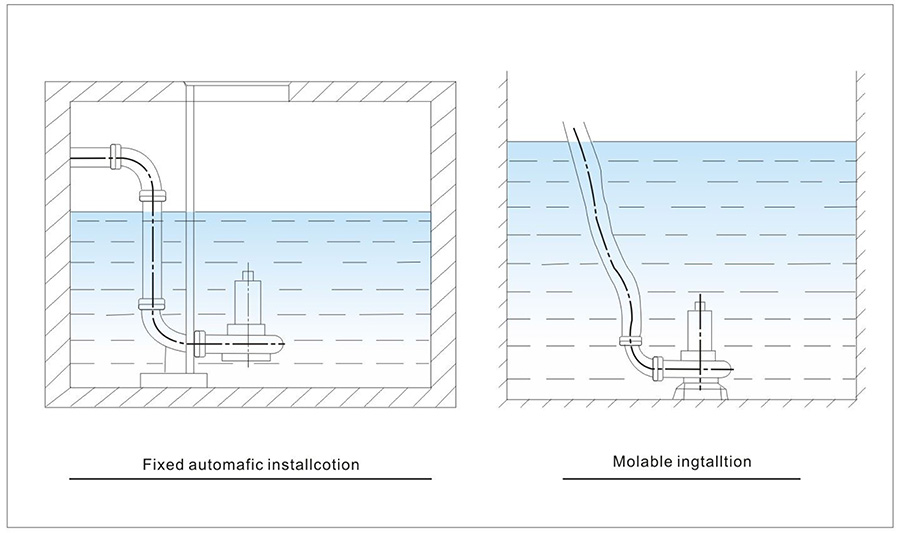

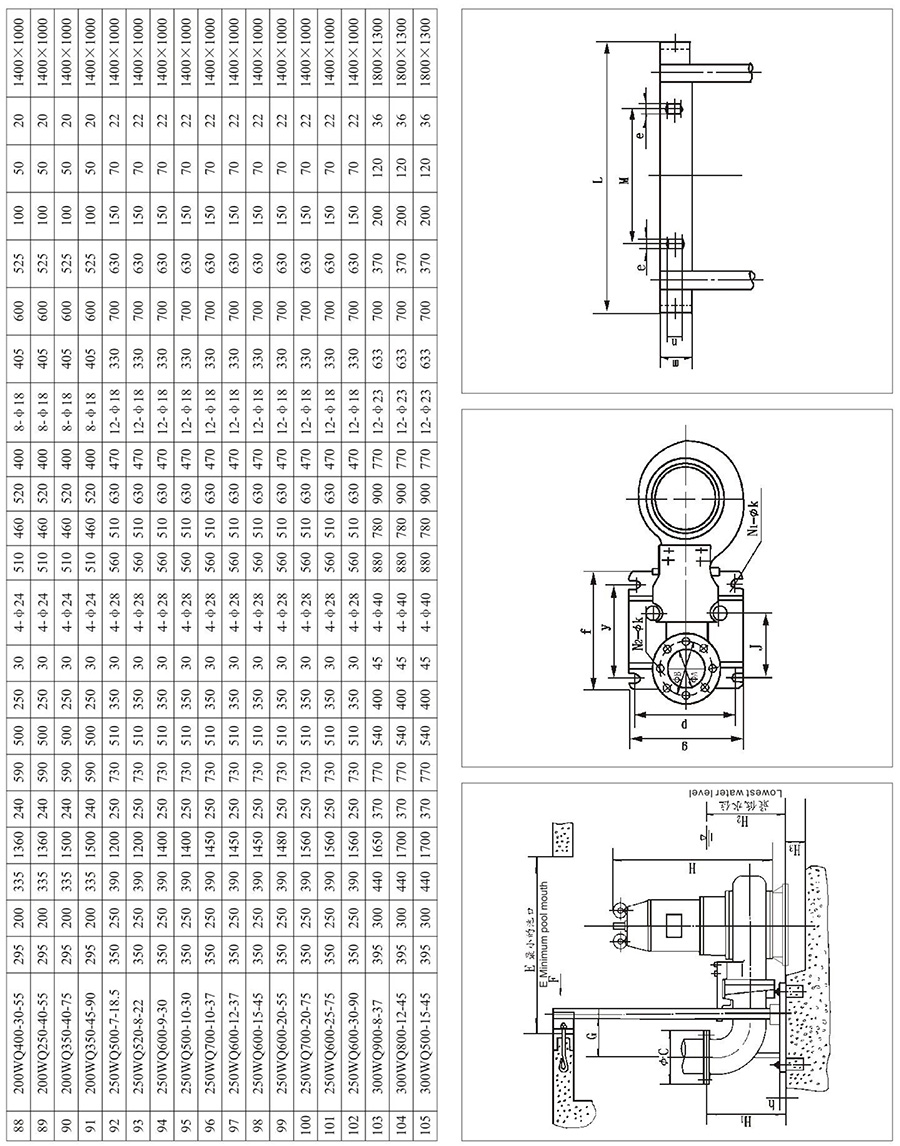

Description of Installation System

1.Automatic coupling installation system It is suitable for long time fix occasion, featuring installing quickly, overhaul and maintenance easily. The system use special foundation, fixed in the bottom of the dredge hole, connecting with the outlet pipeline; installs the assembly rest pad in the top of pool, use the leader to combine them, the purmp has connected with the specially bracket and along the leader reach the foundation then auto-coupled and sealed, automatic fell off while lifting.

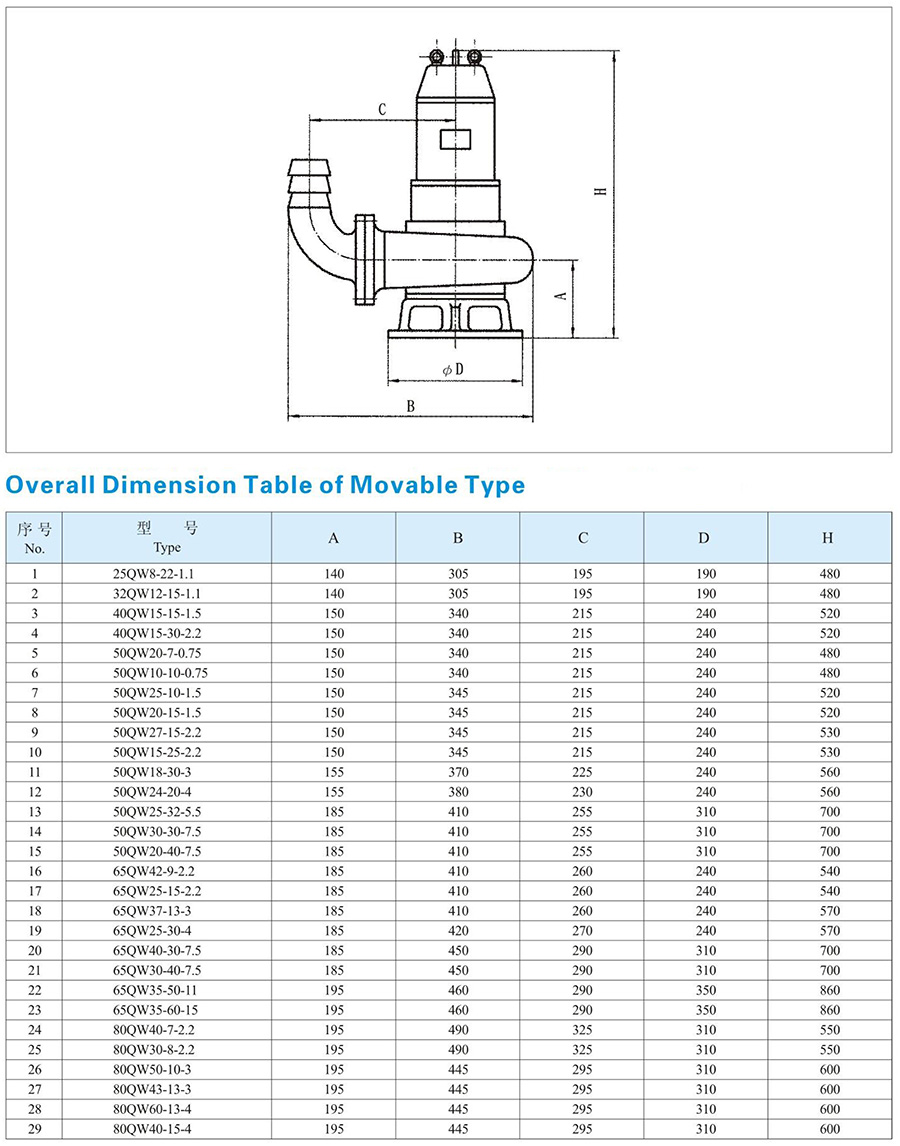

2.Movable installation system

It is supported by bracket, work while connecting outiet tube, this way mainly used for the need of first aid or maintain and construction.

Application and Notice

1.Before working, should check carefully if any damage with the cable, if any looseness or fall-off with the fasteners, if any deformation or damage with pump during transport, storage and installation.

2.Measure the dielectric resistance between the phases and ground with a 500V megohm 2 meter, the value of which has not to be lower than stator megohm, otherwise a drying treatment must be taken for the stator winding of the motor with a temperature not over 120℃

3.This series pump has fixed and movable two kinds. When adopts fixed auto-installed, should make the chain separately rip into (Departure the outlet, its tie wire should parallel to the outiet's) two lifting rings bolt or lifting plate fluctuate lift the pump. Slides down equably along guide rail till auto- coupled. When adopts movable installation, first harnessing the soft pipe, through chain ripping into the two lifting rings fluctuate lifting the pump. Should be careful, cannot use cable as cord avoiding danger.

4.Viewing from the inlet, working pump moves CCW direction. If pump operates reversal, only to exchange any two cables and then connect up.

5.The casing line on ground should strictly connect based on relative rules. Ensure safety, it is strictly prohibited to work under water or move nearby, avoid accidents for electric-leakage.

6.Generally, should assembly full-automatic control cabinet, do not switch directly through eiectric filter or switch blade, in order that pump run well.

7.do not work under lower head for a long time (commonly the using head can not below rated head 60%). It's better work within the advised using head, in case that pump overload and motor burned.

8.Prohibited strictly whole pump set working out of water, which has non-auto circle cooling installation, in case that damage for superheat.

Maintenance

1.The pump needs special person to manage and use, check whether has a good insulation between winding and casing on schedule.

2.After working in a high visc idity liquid, should water pump for few minutes, preventing sediments store in the pump, ensure pump cleanliness.

3.Take pump out of water w hen it does not work for a long time, could not dip in water chronically, reduce affected with damp of stator winding, then extend pump life-span.

4.Generally, after every 300~ 500 hours work should add or replace mechanical oil in oil house (oil No.: 10~30), keep meehanical seal lubricate, then enhance mecbanieal seal's life-span.

5.A fter disassemble and maintenance, casing discreteness should exam through 0.2MPa airtight, ensure motor sealed and reliable.

6.The seal ring between impeller and pump body has advantage on air-proof, once damaged will affect performance of pump directly, so replace when necessary.

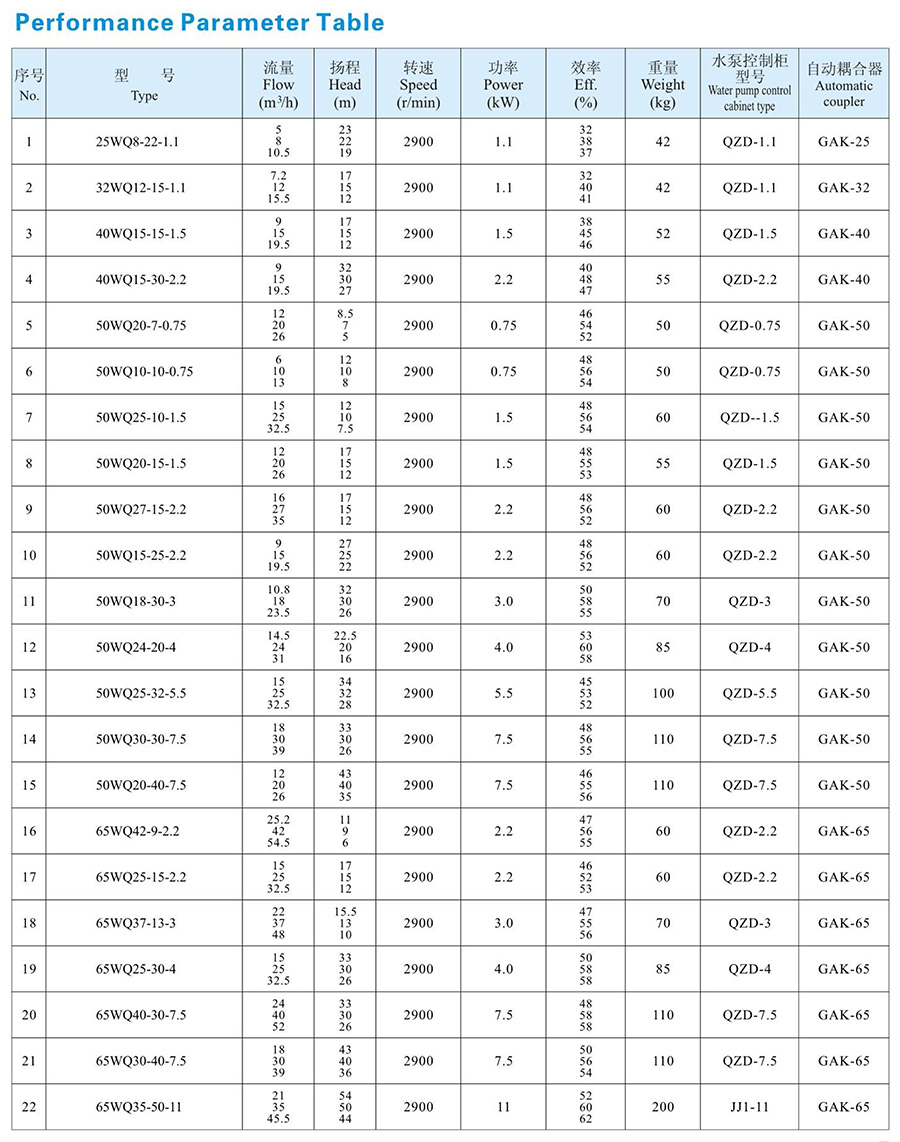

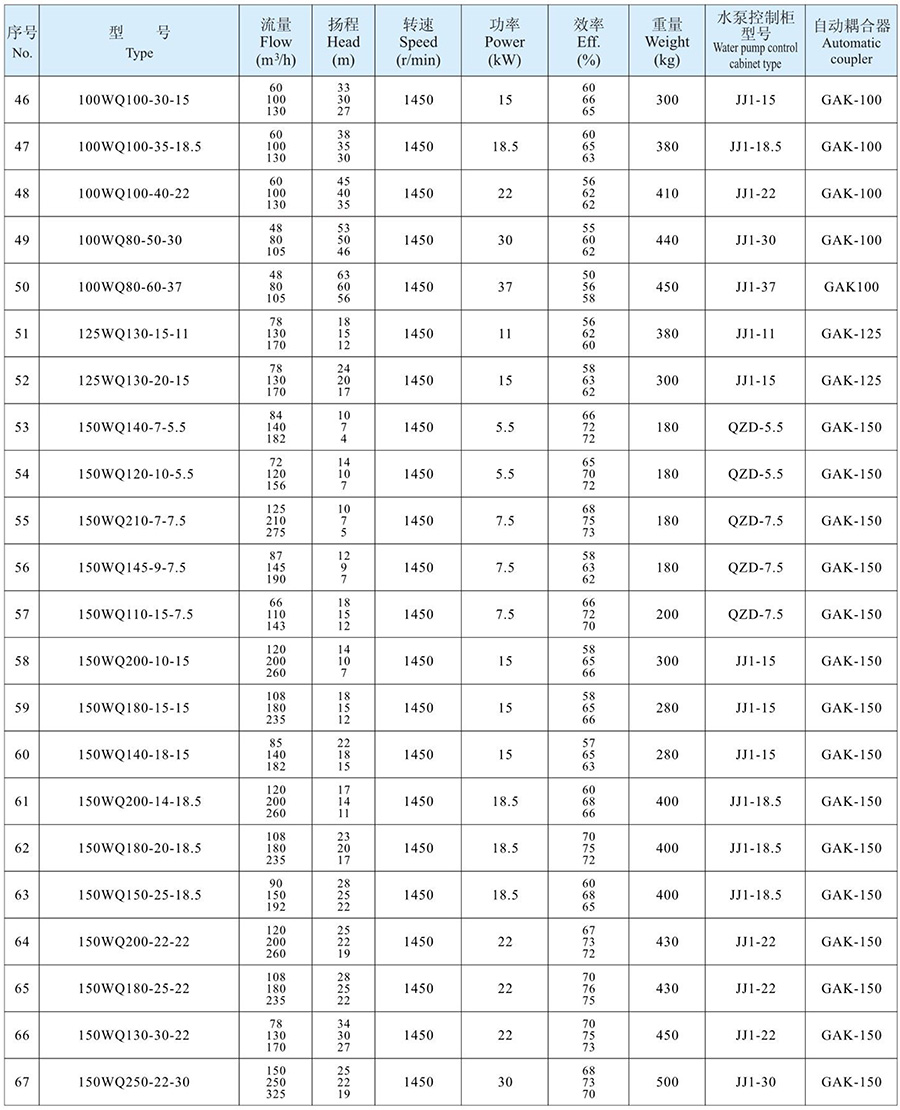

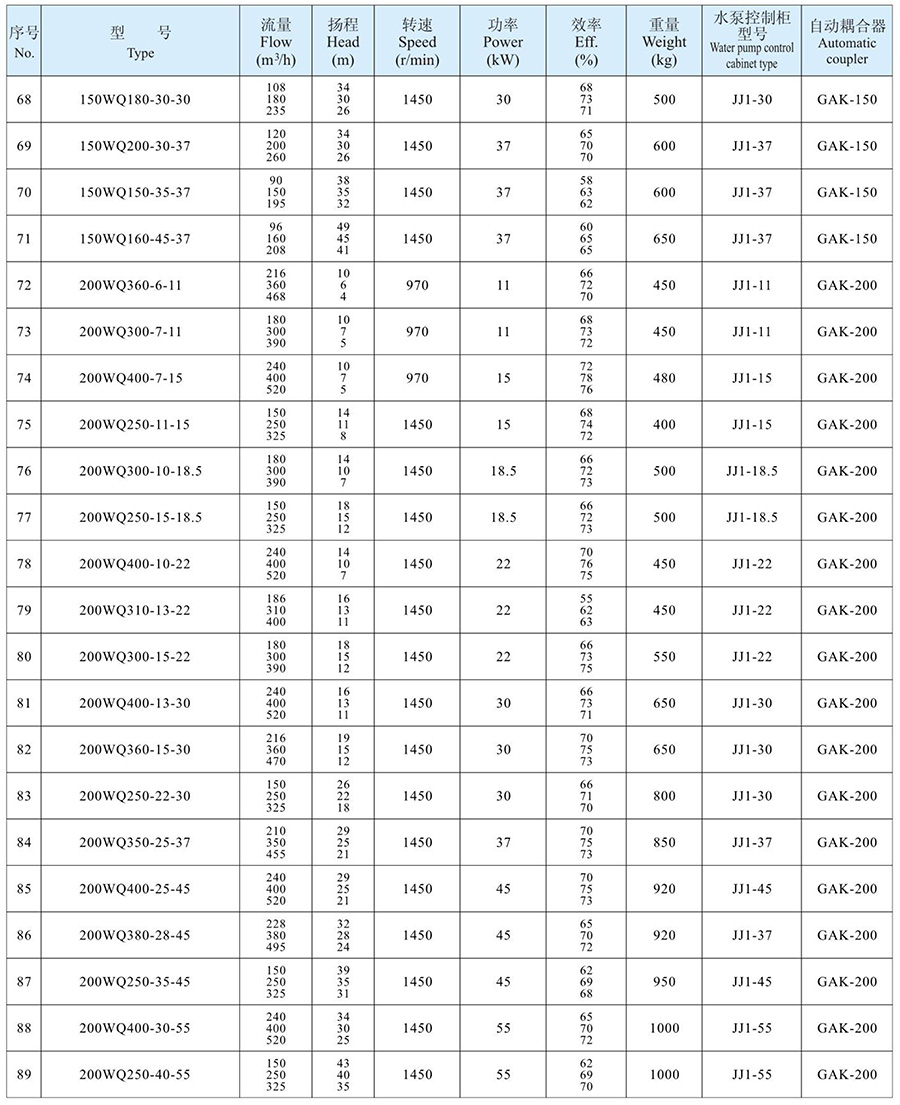

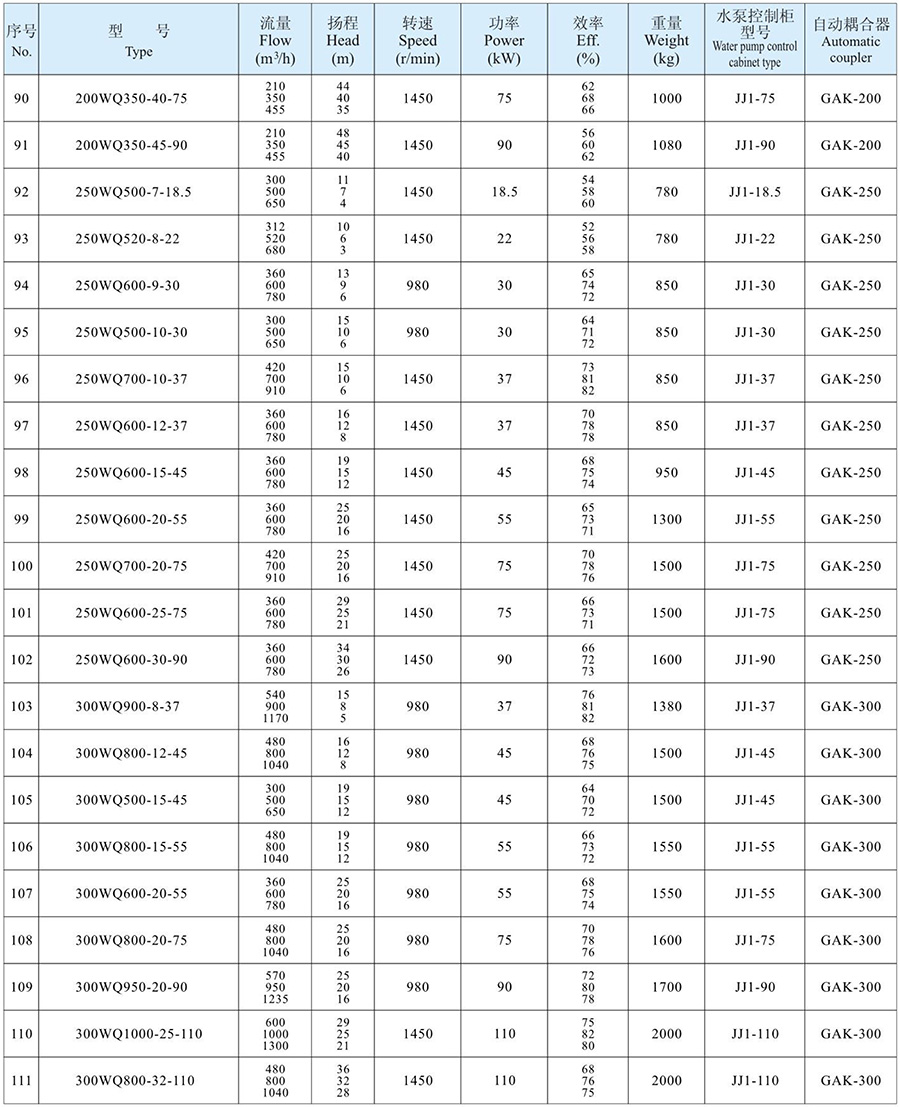

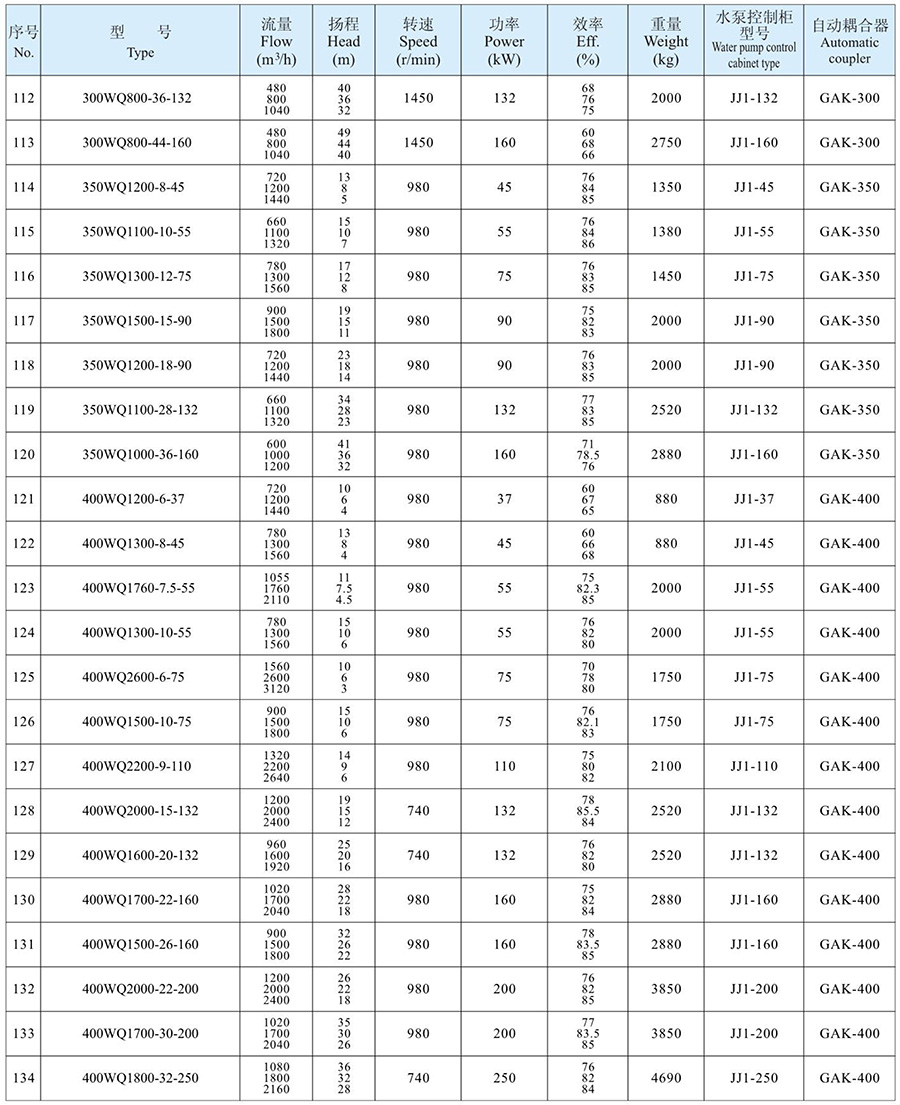

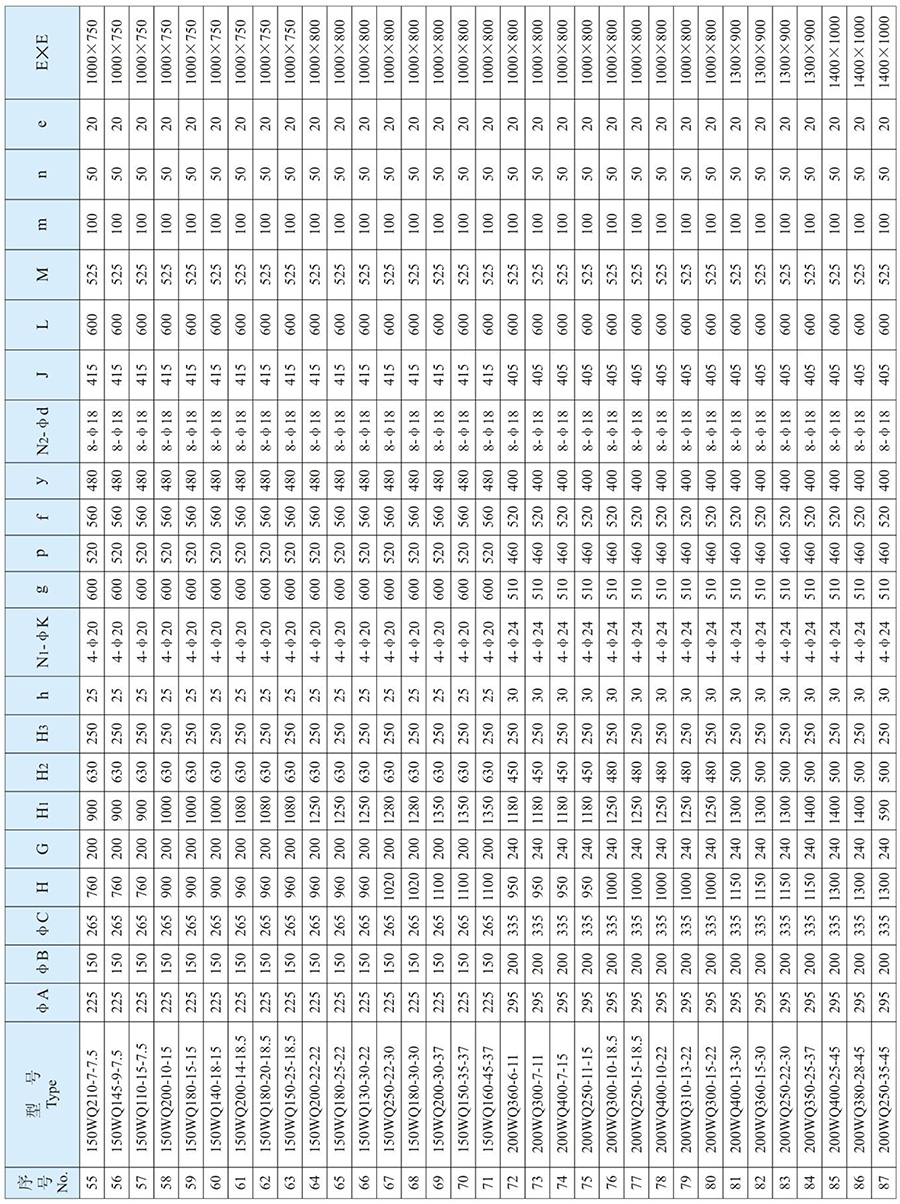

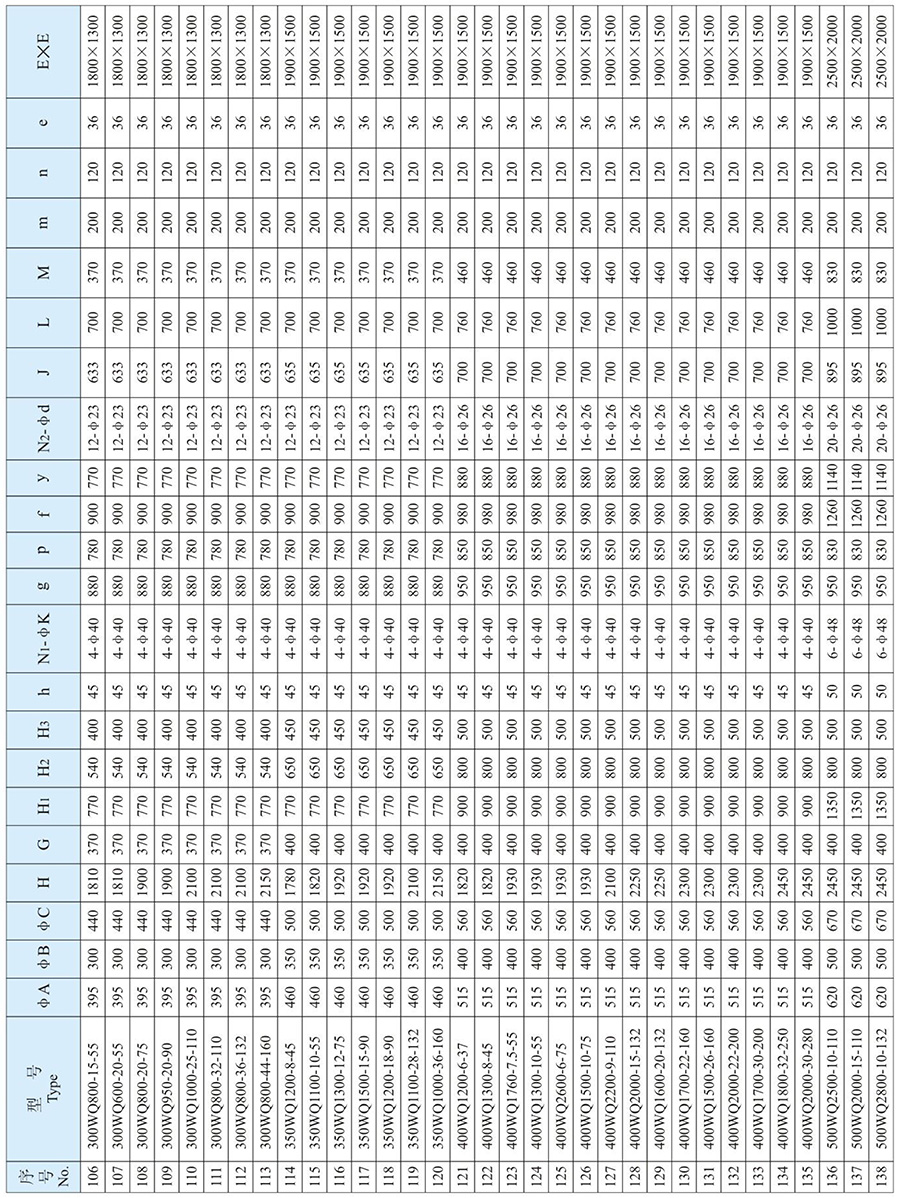

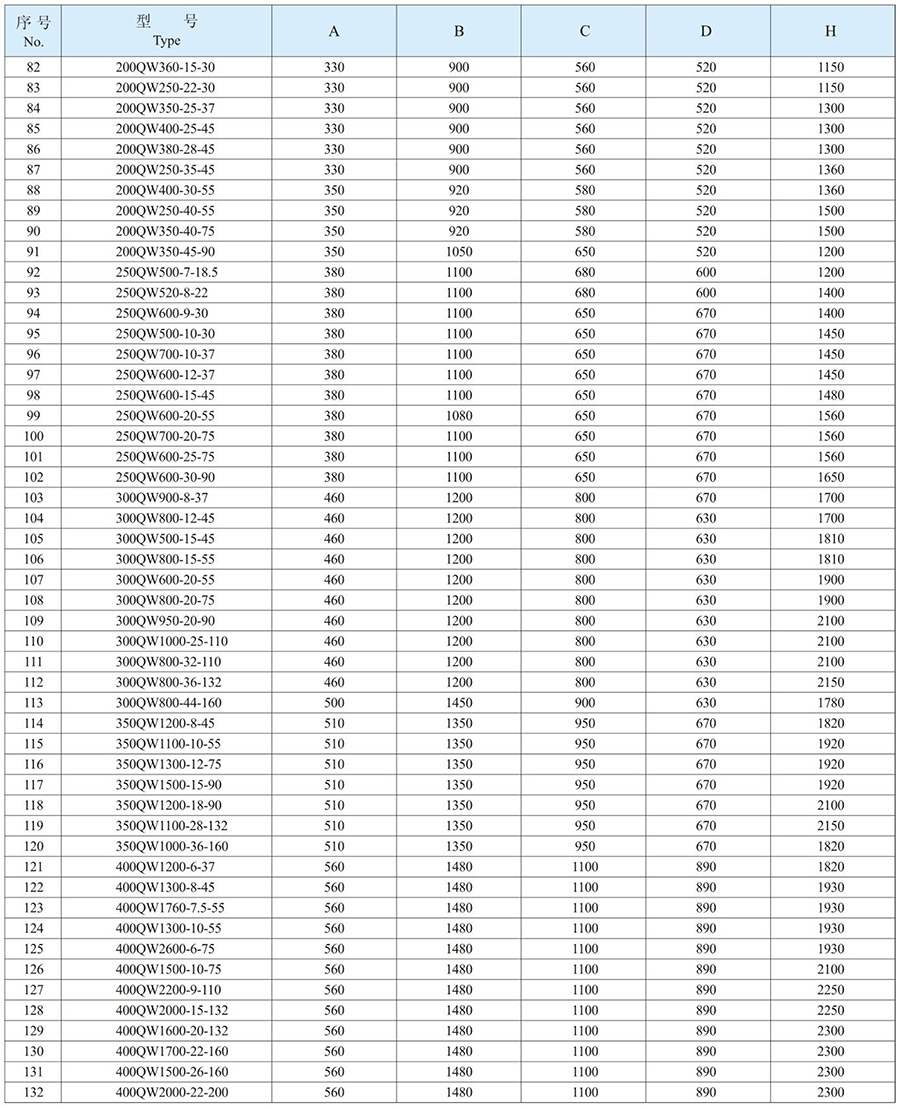

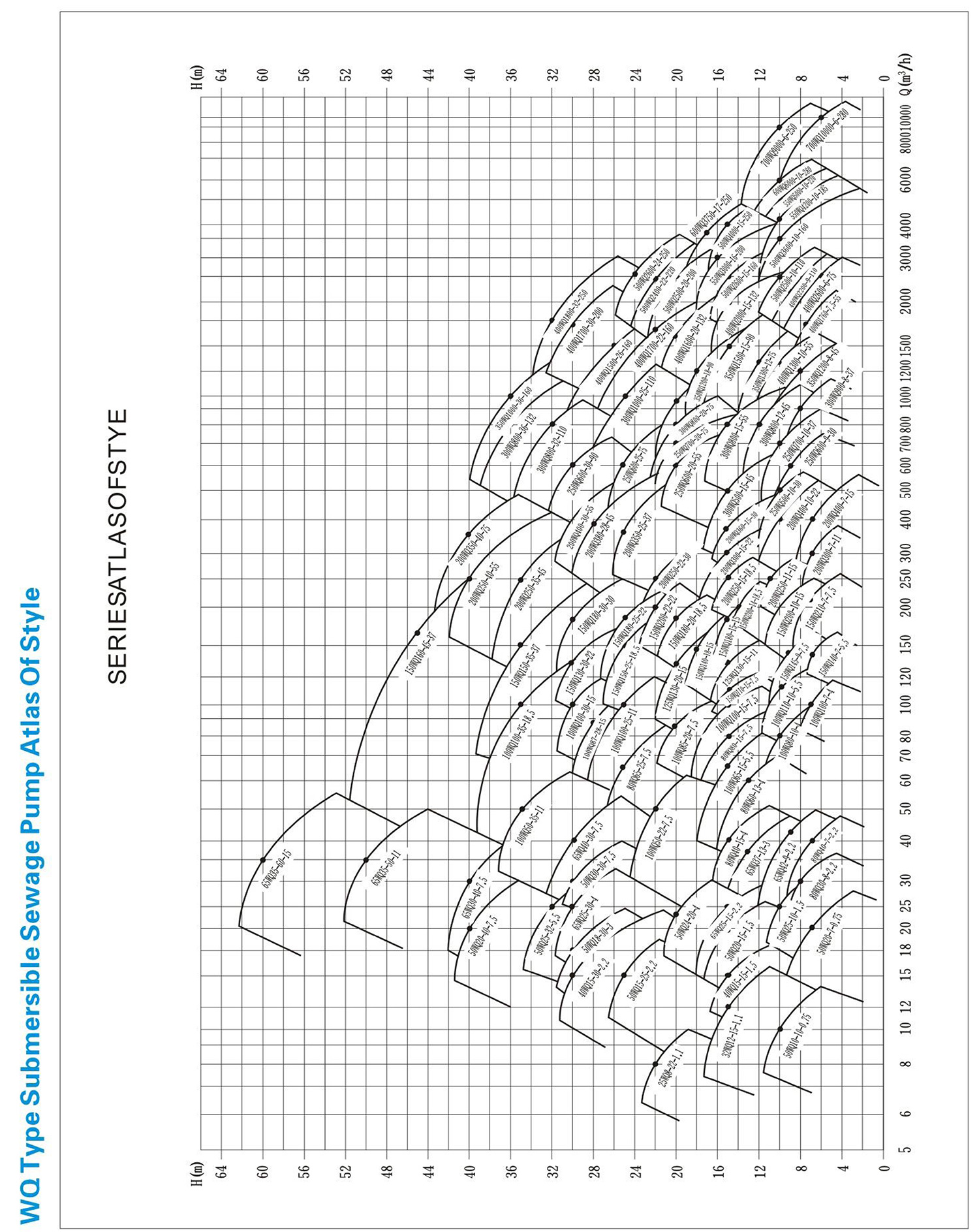

Product Series

Contact Us

Hebei Prime Pump Technology Co., Ltd.

Tel:086-319-7109933, 086-319-7109988

Fax:086-319-7109922

Email:lilixin@plpump.com

Address: No. 69, Lincheng Road, Lincheng Economic Development Zone, Lincheng County, Xingtai City, Hebei Province

Copyright © 2019 Hebei Prime Pump Technology Co., Ltd.